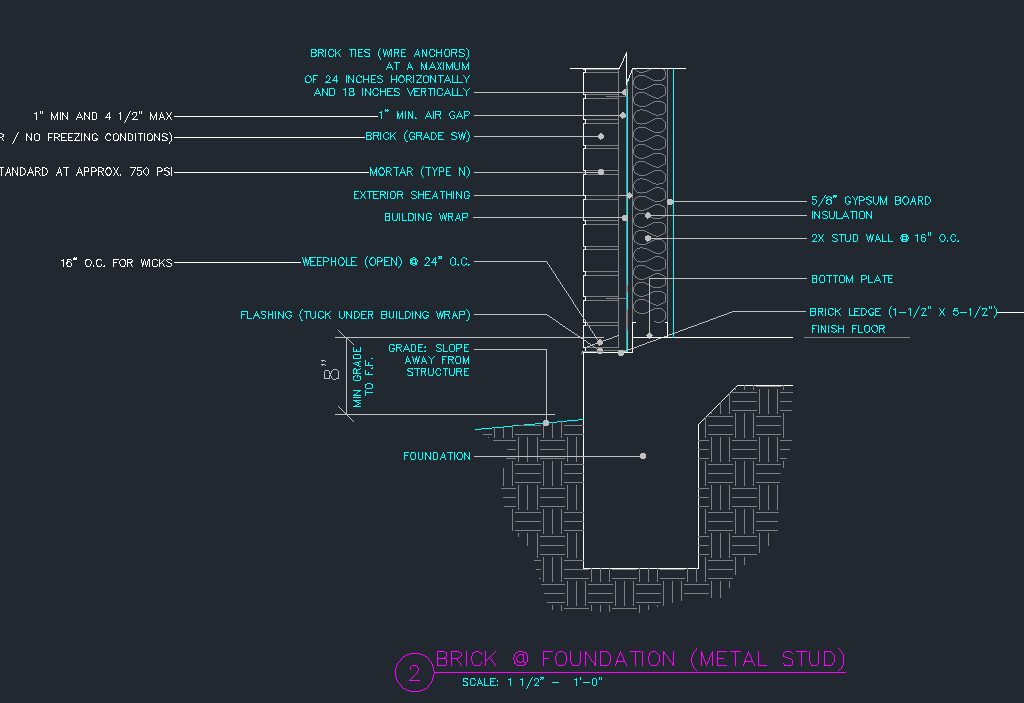

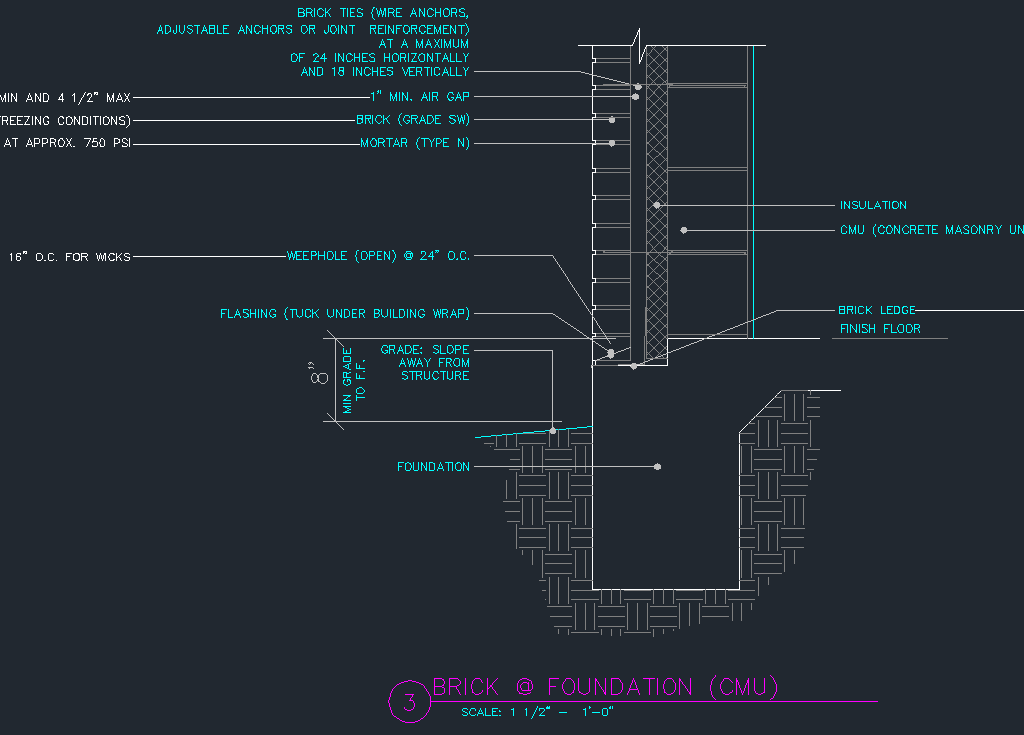

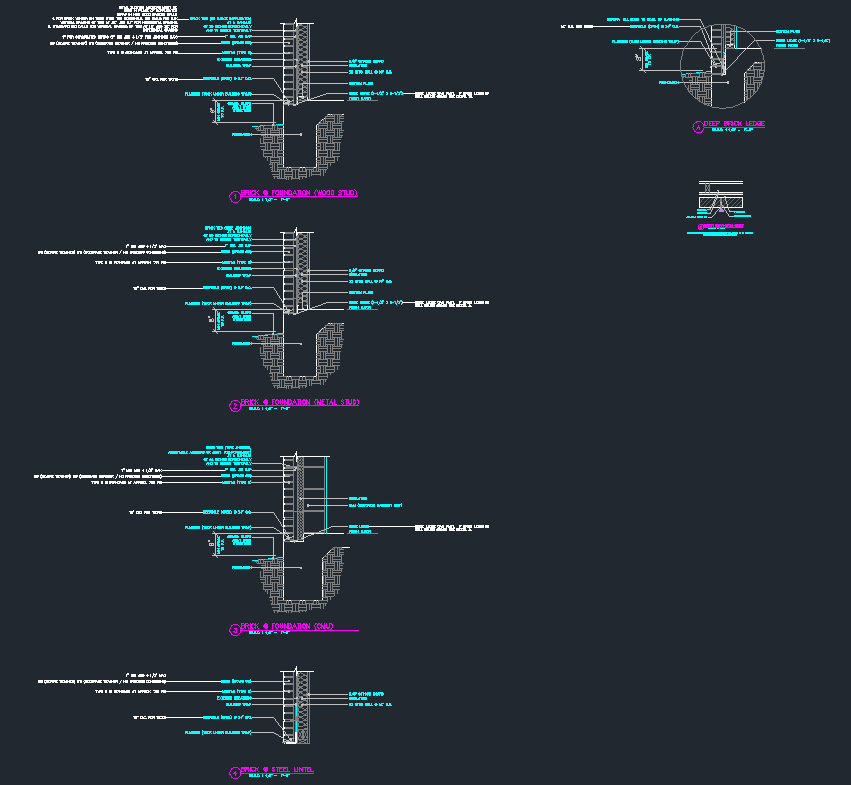

Brick Veneer Details for Wall Sections

Optimize your brick veneer wall assembly with our comprehensive standard details. Our Brick Veneer Wall Sections cover wood stud walls, metal stud walls, and CMU walls, along with expansion joints, brick at steel lintel, and deep brick ledge details.

In the US, brick is predominantly utilized as a veneer system, offering a decorative finish rather than structural support. Our guide focuses on the integration of brick veneer as a non-structural, cover material firmly attached to the structural wall. This adaptable assembly caters to wood stud, metal stud, CMU, or concrete walls, ensuring versatility and reliability in your construction projects.

Brick ledge– Is it necessary and what size should it be? Brick veneer must have a brick ledge to support the brick. From the foundation this is done as part of the concrete footing. The brick ledge should be large enough for the full depth of the brick and be flush with the front edge. The brick ledge should also be set lower than the finish floor level. This is another way to ensure moisture does not enter the interior of the wall assembly. The size and shape of the brick ledge varies widely depending on the contractor. I have always shown them as 1 ½” x 5 ½” so it could be formed with a 2×6. I have on occasion lowered the brick for aesthetic purposes, so the exposed concrete foundation was minimal. These could be formed with wood, styrofoam or cardboard forms. The key is to have the drainage (weepholes) drain below the finish floor and above grade.

How often should weep holes occur? Weep holes should occur every 24” (between every 3 bricks) above all flashing courses. These should be clear of debris and mortar. If wicks are used, they should occur every 16” (between every 2 bricks).

How often should we put expansion joints? Expansion joints in a brick veneer wall should occur every 25’-0” maximum & within 10’-0” of corners and at any offsets or intersections.

What type of tie should be used and how often should they occur? For residential, wood framed construction, corrugated metal strips can be used. For all other applications, wire anchors, adjustable anchors or joint reinforcement should be used. Typical tie spacing should be every 18” vertically and every 32” horizontally.

Should I go with a standard modular brick? This is the most common size of brick that everyone is accustomed to, however, there could be savings by choosing another size of brick. For example, king size brick could offer a significant savings over modular brick. Just be sure the look is what you want and the contractor can document the savings.

What about thin brick? Is this a reliable and cost effective alternative? The answer a majority of the time is no. Thin brick is more expensive than traditional brick (about 30% in my area) and is a different product that is installed completely differently. The look is similar, but that is about it. We have found the only time that we use thin brick is for retrofit situations when we don’t have and can’t add a brick ledge.

What are problems with brick and how do we avoid them? Brick itself, rarely, if ever has problems or fails. It is a fantastic building material. Problems occur when brick walls are not properly drained and retain moisture or water is allowed into the brick assembly. This moisture can remain in the wall cavity, eventually finding its way to the interior of the building or it can lead to efflorescence.

Quick facts:

R Value – 4” face brick is 0.44

STC – 4” face brick is 45

Maintenance Required – Little to none

Life span – Long time (Some warranty for 100 years)

Difficult to install – No, common trade almost everywhere

Design options – Many colors, shapes and sizes available

You must log in to submit a review.